El cuarto de baño

Did you know ......Chemistry helps to provide and save water? While the world's population tripled in the 20th century, the use of renewable water resources has grown six-fold. Within the next 50 years, the world population will increase by another 40 to 50%. This population growth will result in an increasing demand for water and will have consequences for the environment.

Rethinking water and energy consumption works

Reduced laundry temperature

Industry's efforts to develop ingredients that can help lower the wash temperature are a major contribution to potential energy savings. A lot have been developed (such as enzymes) and enable cleaning effi ciency at much lower temperatures! TINOCAT®, an oxidation catalyst helps to deliver the required wash performance at lower temperatures. Oxidation catalysts are used to activate bleach systems in laundry stain removers and detergents.

TINOCAT®, Ciba

As advanced new detergent ingredients have been developed, average wash temperatures have dropped from around 60ºC to 30-40ºC, and in some parts of the world to as low as 20ºC. Shell's range of NEODOL surfactant intermediates are used by most of the world's leading detergent manufacturers. The environmental benefi t consists of huge energy savings..

NEODOL, Shell

PVC: an ideal material for waterpipes

PVC is the material of choice for water pipes. It does not rust, scale, pit or react chemically with the water it conveys. PVC pipes also resist the deposit of bio-fi lm better than most other pipes, helping to provide a consistent water quality to consumers.

The complete phase-out of lead stabilizers by 2015 and increasing the use of recycled PVC are two major commitments of the Vinyl 2010 programme. Novel high performing stabilizers further contribute to the PVC industry's sustainability. These products are compatible with all standard stabilizer systems. As a result, the new stabilized PVC can be safely combined with recycled PVC containing all other types of stabilizer.

ADVAPAK™NEO, Rohm and Haas

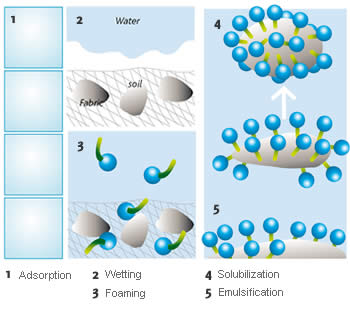

How does the cleaning process work ?

A.I.S.E and Cefi c are currently working on a common information website.

This project currently called WIDE (for «Web Information Detergents Europe») will provide consumers with information and tips on the safe and sustainable use of detergents and maintenance products.

It will also provide more detailed nformation for those interested on ngredient safety information, regulatory environment, initiatives etc.

It is expected to be launched in the second half of 2008.

Much less energy, still clean laundry

Products for personal hygiene and products for cleanliness and maintenance not only are important downstream users of chemicals, but they deliver finished products which contribute strongly to energy savings maintaining the quality of life

Charter for sustainable cleaning

This A.I.S.E. initiative was launched in 2004 in all EU countries plus Norway, Icelnad and Switzerland. It covers all product categories of our industry, whether in the household or industrial/institutional sectors.

Already after 2 years of implementation of this project, this industry could demonstrate savings of 17% of consumed energy and CO2 emmited!

This will continue to be reported as well as other indicators in the industry's yearly sustainability report.

Did you know that the use of fabric conditioners during washing actually helps (or even reduces the need for) ironing? This results in important energy savings for consumers in Europe

Washright: A pan-European campaign for the Sustainable Consumption of household laundry detergents .

In 1999, A.I.S.E. developed its first ever concerted pan-European harmonised TV advertising and PR campaign to encourage consumers to wash sustainably. Millions of laundry packs across Europe carry the Washright consumer information panels promoting best washing practices such as "Use the lowest recommended temperature".

Here are some useful hints if you want to help the environment when doing your laundry

Improvements in energy efficinecy between 2001 and 1996 have saved enough energy to power 900.000 European households for a year.

- Avoid underfilling the machine

- Measure according to soil and water hardness

- Use the lowest recommended temperature

- Reduce packaging waste

Innovation benefiting the environment

Aerogel is a low-density solid-state material derived from gel in which the liquid component of the gel has been replaced with gas. The result is an extremely low density solid with several remarkable properties, most notably its effectiveness as a thermal insulator.

Silica aerogels: in the heat of the light

Silica-aerogel strongly absorbs infrated radiation. it has thus remarkable thermal insulating properties it allows the construction of materials that let light into buildings but trap solar heat! And trapped heat needs not to be produced by your heating system...

Silica aerogel is the most common type of aerogel and the most extensively studied and used. it is a silica-based substance, derived from silica gel. The world's lowest-density solid is a silica nanofoam: it only weighs one miligram per cubic centimeter! Even the desnity of air is slightly higher!

The silica nanofoam has an extremely low thermal conductivity and is consequently an excellent thermal insulation material.

Since aerogel has the equivalent thermal insulating quality equal to 10-20 glass window panes, the fantastic energy conserving effects of an aerogel window replacementwould significantly lower energy consumption and heating bills, partcularly in Northern climates.

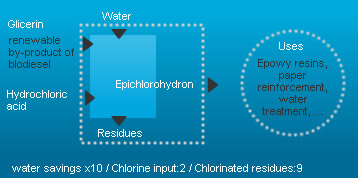

Natural by-product of biodiesel industry gets useful application

Natural glycerin is a by-product of the manufacturing of biodiesel. Worldwide, it is expected than a large volume of thi by-product will be generated in the near future because of the development of this biofuel. Accordingly, it makes sense to give glycerin second lives. One of those is the production of epichlorohydrin which is used in growing markets such as epoxy resins, reinforced paper and the purification of water.

The innovative process named Epicerol® developed by solvay to make epichlorohydrin has the advantage to use natural glycerin instead of propylene, an oil derivative, in order to reduce significantly the environmental impact of the process, in particular by a large reduction of the emission of chlorinated by-products as well as a sharp decrease in water consumption.

This innovation was awarded by the French Pierre Potier trophy "Innovation in chemistry benefiting the environment". A first Epicerol®plant is now running in France and another one will start up in Thailand in 2010.

Epicerol™ process, Solvay